The Patent™ Dental Implant System was developed with the goal of providing the best possible replacement for a lost tooth. Inspired by nature, the system utilizes a unique combination of design, material, and surface topography, which are crucial factors for achieving long-term stable hard- and soft tissues.

Soft-tissue-level design

A soft-tissue-level implant design is a preferable option for achieving optimal biologic performance as it avoids the appearance of a micro-gap at the subgingival level or the level of the crestal bone which would be prone to the penetration of bacteria. Bringing the crown-abutment interface into a visible and controllable area enables patients to maintain good oral hygiene practices.

Additionally, the tulip-shaped transgingival collar mimics the natural shape of teeth, which allows for firm adherence of the surrounding soft tissue, thus reducing irritation. This tight seal also minimizes the risk of pathogenic bacteria advancing past the implant into deeper tissue, which can lead to the development of biological complications such as peri-implant mucositis or peri-implantitis.

A matter of material?

While the material is an important part of the solution, what really matters is how it is processed. Zircon Medical has a specialized manufacturing and zirconia processing method, governed by the highest quality standards, and protected by 14 patents. Patent™ Implants are made in Germany from a special yttrium-stabilized zirconia, which besides being tissue-friendly is highly resistant to fractures, making it the gold standard among all available implant ceramics. One of the main challenges in manufacturing implants from this material is creating a highly rough (Ra 5.7 μm) surface with hydrophilic and osteoconductive properties. Zircon Medical has mastered this with its proprietary manufacturing process.

Unique surface topography

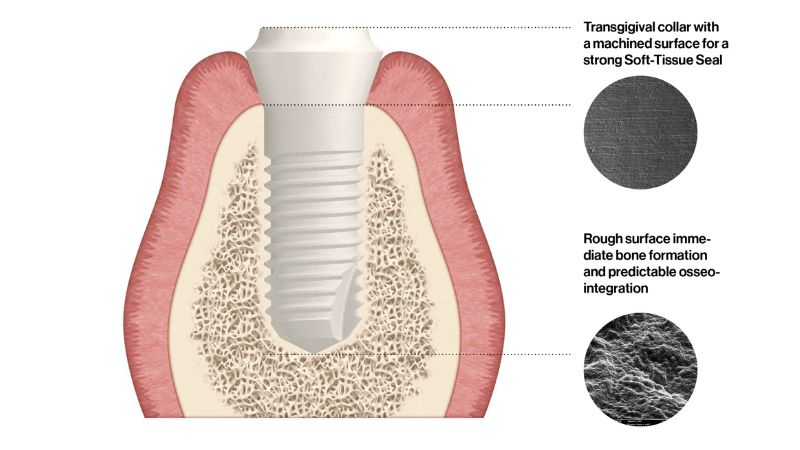

The Patent™ Dental Implant System has a unique surface topography with different roughness levels. The transgingival collar is machined to promote strong soft-tissue adhesion. Histological examinations[1] have proven this adhesion to be so strong that it effectively prevents pathogenic bacteria from penetrating past the implant and infiltrating the soft tissues (soft-tissue seal). This is a crucial factor in maintaining long-term soft-tissue health.

In the osseous portion of the implant, the very rough BBS (blasted before sintering) surface facilitates ideal osteoblast adaptation, leading to fast and reliable osseointegration. Amost immediately after insertion, a fibrin network forms on the implant surface, triggering rapid bone formation in terms of bioinert osteogenesis, consequently shortening the healing time. A preclinical animal study demonstrated over 70% bone-to-implant contact (BIC) after just four weeks of healing, surpassing the performance of all other dental implants previously investigated in similar studies.[1]

Innovative prosthetic concept

Taking inspiration from the natural tooth structure, the Patent™ Prosthetic Concept was developed to provide long-term function and enhanced fracture resistance, while being perfectly compatible with the material properties of zirconia. The final crown interface is connected to a glass fiber post, which has a dentin-like modulus of elasticity, and a zirconia ferrule along the crown-marginal seat. This innovative approach balances mechanical and material performance: the highly stable yet flexible post is able to attenuate masticatory forces and, as a result, virtually eliminate late-term prosthetic complications commonly found in other zirconia-based implant systems.

The completely customizable post, made of high-tech glass fiber, is cemented in the 3C™ implant platform and can be easily prepared using a high-speed diamond bur, allowing clinicians to use their restorative techniques without requiring extensive components or multiple instruments.

References

1. Glauser R, Schupbach P. Early bone formation around immediately placed two-piece tissue-level zirconia implants with a modified surface: an experimental study in the miniature pig mandible. Int J Implant Dent. 2022 Sep 14;8(1):37. doi: 10.1186/s40729-022-00437-z. PMID: 36103094; PMCID: PMC9474793.