The development of the Patent™ Dental Implant System

The surging number of late-term complications such as peri-implantitis demonstrates that implant success must be measured in the long term and that tissue health must be assessed after more than ten years of function. With the aim of developing a tooth replacement solution that facilitates long-term health and function while eliminating the drawbacks of conventional screw-retained implant systems, implant specialist Dr. Wolfgang Winges invented the Patent™ Dental Implant System together with Dr. Johan Feith. In the following interview, Dr. Winges talks about the development of the Patent™ Implant and its scientifically proven long-term success.

Dr. Winges, what long-term clinical results have you observed with the Patent™ Dental Implant System?

I have been practicing implant surgery for 34 years now and have been using the Patent™ Implant since 2004. The long-term results I have observed with it are in line with the findings from the prospective nine-year study conducted at Heinrich Heine University Düsseldorf, Germany: Around many of these implants, I have seen a bone increase and often even an increase in keratinized gingiva. Thanks to the ideal machined surface of the transgingival portion of the Patent™ Implant, a veritable soft-tissue seal forms around the implant in this area. This tissue friendliness is exactly what Prof. Jürgen Becker highlights in their study: He found an increase in keratinized gingiva around all Patent™ Implants examined at the nine-year follow-up. Prof. Becker reported that this was a unique occurrence—he had never experienced anything like it before. Furthermore, I have not experienced any fractures to date. I have had an approximate success rate of 95.8% for all the Patent™ Implants that I have placed over the past 18 years.

What was the rationale behind the development of the Patent™ Dental Implant System?

I developed the Patent™ Implant together with Dr. Feith. Having placed approximately 40,000 implants altogether, we have a great deal of experience in implant treatment. In the Brånemark surgery courses that we have led in Munich and Bad Hersfeld, Germany, since 1994, we often saw losses of titanium implants that we could not explain—despite good oral hygiene and stable occlusion. Today we know that free titanium particles that are present in the tissue surrounding dental implants can trigger an immune response, leading to peri-implant bone resorption and later to implant loss. In addition, since the implant systems at that time were rather complicated, we wanted to create a simplified solution that eliminates the need for screwdrivers or screws. We also wanted to eliminate the problem of screw loosening and move the bacteria-prone implant–abutment gap away from the subgingival level, where it cannot be controlled or cleaned. Lastly, we wanted to use a material that does not trigger the immune system in any way and that matches the color of a natural tooth.

Why did you choose not to use a screw-retained internal connection, like what is found in titanium implants, for the two-piece Patent™ Implant?

Prof. Andrea Mombelli once said that you cannot simply transfer the blueprints of titanium implants to ceramic implantology, but that is exactly what is being done with screw-retained ceramic implants. Unlike titanium, ceramic is a rigid material and cannot be cold-welded. Material scientists also agree on this: Two components with these same material properties, that is, the same stiffness, cannot be connected in a way that ensures long-term stability. If you were to screw a ceramic abutment onto a ceramic implant, you would create an enormous amount of material stress and increase the risk of fracture as a result. Also, a screwed connection can never be secured: In the long term, loosening of the screw will always occur. Additionally, in traditional implants with a screw-retained connection, a micro gap forms under function, into which bacteria can penetrate—this has been shown in studies by Holger Zipprich and Prof. Daniel Olmedo. Regardless of the type of screw connection and the implant material, bacterial penetration of this gap always occurs. The resulting microinflammation can initially cause mucositis and develop into peri-implantitis. With screw-retained ceramic implants, this gap is even greater, since ceramic is not ductile but completely rigid. We wanted to eliminate these inherent problems.

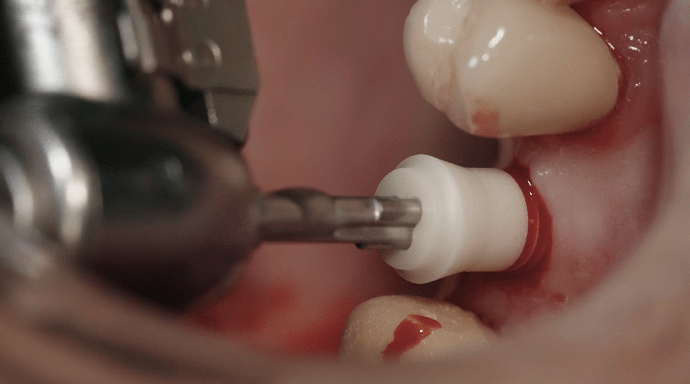

Instead of a screwed prosthetic connection, a glass fiber post is cemented onto the two-piece Patent™ Implant. Why this novel design?

We wanted to avoid a screwed connection and to move the gap away from the subgingival level to the region accessible to natural cleaning, namely to the free gingival margin—and in the posterior region when possible even supragingival. However, a cemented zirconia abutment would have created a high degree of material stress. Therefore, we looked at what nature had originally developed: The main component of a tooth is dentin, which is far more flexible than enamel in the area of the crown. The glass fiber post, which is cemented onto the two-piece Patent™ Implant as a prosthetic buildup, acts like a stress breaker thanks to its dentin-like properties. The masticatory function is ultimately stabilized through the crown, which has enamel-like properties. One could say that the two-piece Patent™ Implant mimics the structure of a natural tooth. Another advantage lies in the ease of revision: Should a glass fiber post break, for example as a result of bruxism, it can be easily removed from the implant and replaced.

Dr. Wolfgang Winges developed the Patent™ Dental Implant System together with Dr. Johan Feith.

Dr. Wolfgang Winges developed the Patent™ Dental Implant System together with Dr. Johan Feith.

Dr. Wolfgang Winges has been using the Patent™ Dental Implant System since 2004.

Dr. Wolfgang Winges has been using the Patent™ Dental Implant System since 2004.

Do novices to the Patent™ System have to learn a lot of new things in terms of prosthetic restoration?

Practitioners can easily apply their existing prosthetic knowledge on natural teeth in the same way on the Patent™ Implant. The glass fiber post is prepared intraorally in the exact same way a natural tooth or a post and core in endodontics is prepared—we all learned that during our studies and while training in dental practices. Either a conventional impression of the implant can be taken, or it can be scanned—either with or without a cemented post. It is up to the practitioner to determine his or her prosthetic workflow. This allows for a myriad of treatment options. Bars can be attached to Patent™ Implants, tapered crowns can be realized, and the implants can be combined with natural teeth—everything that is possible in the field of classic prosthetics with titanium implants is possible in the same way with Patent™ Implants.

For a long time, the main challenge with ceramic implants was their ability to osseointegrate. How has the Patent™ Implant mastered this?

High surface roughness is crucial for the osseointegration of ceramic implants. The systems offered at the turn of the millennium, which had relatively smooth surfaces, were in no way comparable to titanium implants as regards bone healing success. The crux lies in the manufacturing process: After sintering, zirconia is so hard that it is very difficult to carry out a surface treatment. After countless tests, for instance, at the Fraunhofer institute in Munich, we developed and patented a highly complex process in which the Patent™ Implant is blasted and roughened in the pre-sintering phase, creating a maximum surface roughness that bone cells love. Drs. Roland Glauser and Peter Schüpbach’s preclinical study demonstrated that the Patent™ Implant surface achieves an unprecedented osseointegration success of bone-to-implant contact of over 70% after only four weeks of healing. It is currently the ne plus ultra in the field of ceramic implantology—there is no better surface.

After almost 20 years of clinical use and based on a solid foundation of scientific data, Patent™ has a great deal of evidence supporting its use. Why is this so significant for practitioners and patients?

This is one of the key advantages of the Patent™ Dental Implant System. Dr. Sammy Noumbissi, president of the US-based International Academy of Ceramic Implantology, recently said that Patent™ is the first two-piece zirconia implant he knows of that has come to market with nine years of scientific data behind it. There has never been anything like it before. On the advice of our patent attorney, Dr. Feith and I had already started collecting data, forming a small circle of users, and initiating clinical studies, such as the one conducted by Prof. Becker, right from the outset. Today, the Patent™ Implant is unique among commercially available zirconia implants with its large evidence base. It offers dentists who are looking to start using ceramic implants a high degree of confidence in terms of their decision-making and in their communication with their patients.

The surface of the Patent™ Implant is hydrophilic, attracting blood at a particularly high degree.

Dr. Wolfgang Winges has been practicing implant surgery for 34 years now. He is based in the German city of Bad Hersfeld in Hessia.

Dr. Wolfgang Winges has been practicing implant surgery for 34 years now. He is based in the German city of Bad Hersfeld in Hessia.How do you see the Patent™ technology playing a role in mainstream tooth replacements, considering that Titanium implants are the standard of care?

Now that we have sufficient evidence that Patent™ Dental Implants can maintain hard- and soft-tissue health and stability over an extended period of time, we as an industry have the responsibility to revisit the definition of implant success. Dr. Feith and I asked ourselves as we were developing the Patent™ System whether it’s acceptable to factor into our tooth replacement treatments long-term complications like screw loosening and peri-implant infections. It was clear to both of us from the beginning that we have a responsibility to our patients and to our profession to keep evolving the clinical performance of the technologies we use to repair and replace vital human biological structures. We as a profession have the responsibility to push the boundaries of success, rather than re-treat a solution that has become increasingly difficult to maintain over time. Patent™ is the first of its kind in achieving this healthy accomplishment, and I know that the team at Zircon Medical is working diligently to continue to build upon our successful track record. I’m excited to see what the future holds!